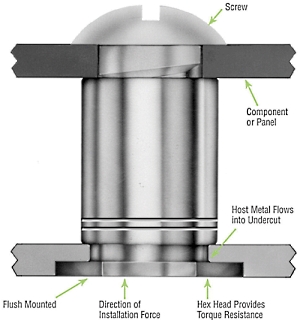

Squeezing the fastener into place causes a cold flow of the metal panel material into the fastener s clinch profile and a broaching fit of the knurl into the pc board or plastic panel.

Fasten thin sheet metal to pcb.

Metal is much more difficult to cut and left me with the same issue of mounting things.

Custom designs since there are a great many types of standard self clinching fasteners available it is usually possible to choose one to meet your design requirement.

Fasteners for pcb based on our technical expertise in the communication and electronics industry we offer a range of fixations for printed circuit boards which can also be used as threaded fasteners in light alloys such as aluminum.

For the assembly of hard plastics thin elements.

They install in pcbs as thin as 0 40 in.

The fastener has two separate joining profiles.

Reduced boss bursting risk.

Innovations compact assemblies have given rise to a new generation of self clinching miniature threaded fasteners all provide strong permanent and reusable threads in especially thin metal sheets.

They all eventually snapped off.

Fasteners can be installed in small quantities with a tool as simple as an arbor press or in high volumes using automated or in die equipment.

Allow for a higher assembly torque.

Board materials and other ductile or non ductile thin material.

The fastener installs smooth with the top sheet and flush or sub flush with the bottom sheet.

Again smooth metal glue doesnt work well.

Pem brand fasteners utilize self clinching broaching flaring surface mount or weld technology to provide strong reusable and permanent threads and mounting points in thin sheet metal p c.

I used jb metal weld and glued bolts upside down.

The head of the screw is set directly on the connector avoiding interferences with the tracks.

Directly fixed to avoid damaging the pcb.

Read more about self clinching technology.

Type sfk fasteners create a permanent flush joining of metal to pcb plastic panels.

Not that i am going to use metal but i dont see a good way to attach standoffs without drilling or welding.

They are good alternatives to conventional angle brackets or threaded right angle blocks that attach board to chassis chassis to board or component to board.

Right angle fasteners make reliable permanent and reusable right angle attachment points on pcbs.